Our approach tosustainability

Sanwa Kogyo is a specialist manufacturer of soft packaging materials.

Japan has a long history of packaging dating back to around 4,000 B.C., when hemp cloth was apparently already being used to wrap food.

The forms of packaging evolved from clay kilns, wooden tubs and barrels through to the Edo Period when a variety of materials were used to create packaging materials according to the purpose of use, including soil, wood, bamboo, straw, hemp, cloth and paper. Moreover, these packaging materials have become more and more elaborate in their decorations and embellishments.

Nowadays, Japan is known for its skills and techniques in decoratively wrapping items in a way that is far superior to other countries. So, one could say Japan has a culture of wrapping items that has evolved from ancient times.

In these modern times when countless products emerge on and then disappear from the market, the need for packaging materials has become even more in-depth, diversified, and complex.

At Sanwa Kogyo, we are keenly aware of the needs of customers and markets that change with the times. We are using our distinctive development capabilities to create and manufacture the best quality packaging materials, as we contribute to cultivating the important culture of packaging.

Quality Policy

- 1)We will follow the relevant laws and regulations, conform to requirements, and evaluate the effectiveness of and continually improve on quality management systems, as we work to enhance product quality and boost customer satisfaction.

- 2)We will make all employees in the company aware of the importance of meeting our customers’ requirements.

- 3)In each department, we will set targets for quality that are aligned with the Quality Policy, and implement and maintain these targets.

- 4)We will make the Quality Policy available to all employees, so that they can learn and know about it.

- 5)We will carry out a management review to evaluate and review the appropriateness of the Quality Policy.

- 6)We will respect the personality and individuality of each employee, and cultivate a corporate culture where all employees can freely and openly demonstrate their creativity.

- 7)We will strictly protect and manage the company’s confidential information, personal information, and customer information.

- 8)Each employee will continue to their efforts for self improvement and innovation, as a corporate worker engaged in highly specialized and creative work.

- 9)We will use our technologies that are always up to date to create and provide superior products that are useful in society and contribute to the wider society, and acquire the trust and confidence of our customers, clients and business partners.

Quality control system

Thorough quality control that allows for integrated production.

Beautiful printing without the ink fading or any misalignments or other errors. Lamination that requires micron-level accuracy to achieve a uniform thickness. These are just some of the various requirements that we have to completely clear as a manufacturer. We believe that even if there is one defective product in tens of thousands of items, we cannot call that a perfect product creation. So, this is why Sanwa Kogyo is focused on thorough quality control. In addition to performing checks at each process, we also carefully inspect the products right up to the final stage as a part of our efforts to achieve zero defective products. Our sense of duty to deliver on quality doesn’t end at the finished product - it reaches as far back as the planning stage. We are committed to stringent quality control in both the hard area of product development and the soft area of management and communication skills.

We are able to create the highest-quality products using our employees’ unique skills, character and actions in proposing original designs, and our extensive range of equipment and facilities.

We are actively investing in both the quality control of products, and also in state-of-the-art equipment and facilities to commercialize various product plans. Sanwa Kogyo was one of the first companies to start using early on a 10-color Gravure printing machine, and to introduce other advanced equipment such as one of the best extrusion lamination and dry lamination machines in all of Japan. We are working to improve our capabilities in both the hard area of product development and the soft area of management and communication skills. Our commitment to quality is one of the reasons why we have earned the considerable confidence and trust of top manufacturers.

Food and snacks

-

Roll products

-

Paper products

-

Zippered bags

-

Self standing bags

Production system

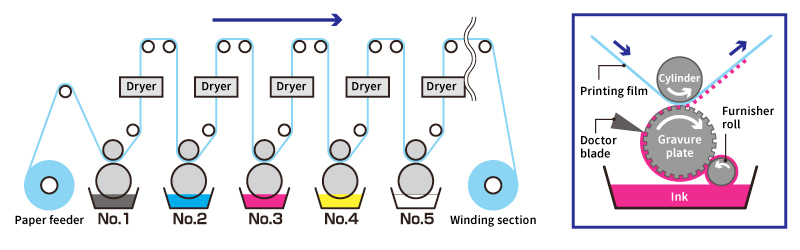

Features of the Gravure printing machine

Gravure printing is an intaglio (indented) printing method that uses metal roll plates. The designs for printing are carved into the surface of the plates, and the ink in the indented (depressed) areas is transferred onto the printing substrate. Gravure printing excels in depicting in detail light and dark shades, and also in skillfully recreating photographic images. Moreover, the plates are highly durable, which makes Gravure printing suitable for high-speed and large-lot printing and widely used for not only food products but also for numerous packaging materials.

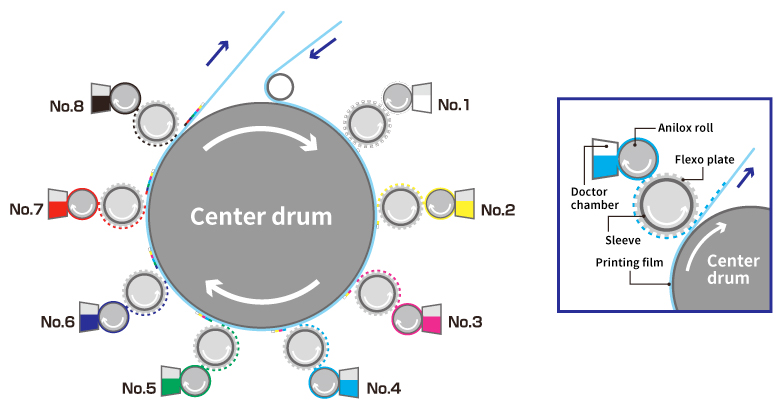

Features of the Flexo printing machinee

Flexo printing is a relief (letterpress) printing method that uses resin (plastic) plates. Although the reproduction of light and dark shades is slightly inferior compared to Gravure printing, Flexo printing recreates much sharper and stronger detailed patterns and fine lettering. In addition to using less ink for coating than Gravure printing, as we are using water-based printing at Sanwa Kogyo, we can substantially reduce CO2 emissions by using Flexo printing as this method does not emit any VOC or require combustion

Access

■Tsubakidani Plant

1725-1 Kishinoue, Manno-cho, Nakatado-gun, Kagawa

■Manno Plant 1 / Manno Plant 2

1893-1 Hazama, Manno-cho, Nakatado-gun, Kagawa

Tel. +81-877-75-3606 (Main line)

Tel.

+81-877-75-3606

(Main line)